About Kanex

Manufacturing products that meet needs is manufacturing

that looks beyond the times.

One item at a time, one day at a time.

Precise, accurate, and dedicated.

There is manufacturing that can meet the needs that are right in front of us because we have focused on our products.

This also means manufacturing that is one step ahead of the times.

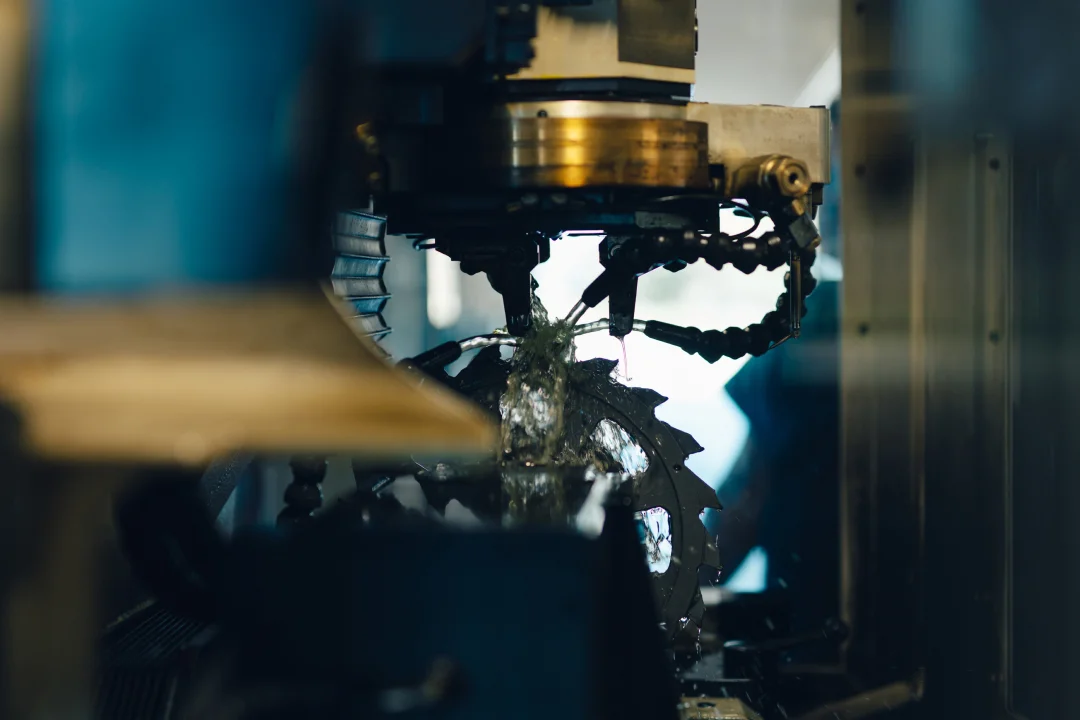

Cutting tools that can be created in any shape are born from flexible ideas that can respond to any needs.

With this belief in mind, we have taken on the challenges that lie in front of us.

We will continue to take on the challenge of creating new value that does not yet exist in the world, with the feeling of “We can become whatever shape we want.”

Strengths of KANEX HAMONO KOGYO CO.,LTD

100% custom-made manufacturing

We manufacture all cutlery in small batches of a wide variety of products, all made to order, without having to keep inventory. Because we have built an integrated production system in our own factory, from development and design to manufacturing and after-sales service, we are able to manufacture products with virtually no complaints.

Short delivery times can also be negotiated.

Due to our integrated production system, we can respond flexibly to short-term production with our quick response and team strength, so please feel free to contact us. Because we work on custom-made products, we also specialize in custom-made products such as prototypes.

Proposal type for problem solving

Solving customers’ problems, issues, and concerns is the essence of manufacturing, which we value. We take on challenges with flexible thinking, such as “Can this material be used?” and “Others have refused.”

(message)

Precisely, accurate.

We have focused on wholeheartedly.

We create new value through daily efforts.

Since its founding in 1957 as SUGI KANAMONO TEN, KANEX HAMONO KOGYO CO.,LTD has been dedicated to the production and maintenance of cutlery for over 60 years. We have been working on each product with precision and accuracy, with a commitment to manufacturing. That will continue. As a manufacturing company, our management philosophy is “Progress to the next stage,” so that by accumulating daily efforts, we will lead to growth and rise to the next stage and the next world. We have been working hard to create cutlery that can be made into any shape. That is why we will continue to take on the challenge of responding flexibly to changes in the times and becoming whatever shape we want to be.

Company Profile

JAPAN

- Trade name

- KANEX HAMONO KOGYO CO.,LTD

- Representative

- Ryusuke Sugi

- Founding

- 1957

- Capital

- 10 million yen

- Business details

- Manufacture, sales, regrinding, and maintenance of industrial tools (carbide tools, diamond tools)

- Office information

HEADQUARTERS&FACTORY

831-0013 783 Nakahachiin, Okawa City, Fukuoka Prefecture

TEL (+81) 0944-88-1708

FAX (+81) 0944-87-3094NAGOYA OFFICE

456-0064 1-125 Koshincho, Atsuta-ku, Nagoya City Aichi Prefecture

TEL (+81) 052-678-5251

FAX (+81) 052-678-5253

CHINA

- Trade name

- KANEX TOOL (NANTONG) CO,.LTD

- Representative

- Toshitaka Sugi

- Founding

- 2004

- Capital

- 770,000 USD

- Office information

HEADQUARTERS&FACTORY

226000 Nantong City, Jiangsu Province No. 88, Hongxing Road, Economic and Technological Development Zone

TEL (+86) 513-8592-2830

FAX (+86) 513-8592-7391

VIETNAM

- Trade name

- VIET NAM KANEX COMPANY LIMITED

- Representative

- Toshitaka Sugi

- Founding

- 2013

- Capital

- 150,000 USD

- Office information

HEADQUARTERS

No.225, Hai Ba Trung st, Ward Vo Thi Sau, District 03, Ho Chi Minh City, Viet Nam

TEL (+84) 83-820-6939

FAX (+84) 83-820-0163